In a previous post, we described a solution to working with very large CAD files in wearable devices, one of the practical challenges we've faced when applying Mixed Reality technology to real life scenarios on construction sites. In this post, let's take a look at a little background.

In 2017, Skanska wanted to explore the feasibility of using HoloLens on construction sites. We built an app that loaded CAD and BIM models, placed them on site – but inevitably, the effort fell short in the end. The models were simply too big and complex to work with efficiently using a mobile device.

After the first projects, we iterated on a solution that would be capable of handling building models of "unlimited size" – along with the associated project data, everything from snagging, to schedules, to check lists and audit protocols. By adding a mobile planning tool, we tried to simplify the process of preparing the daily work.

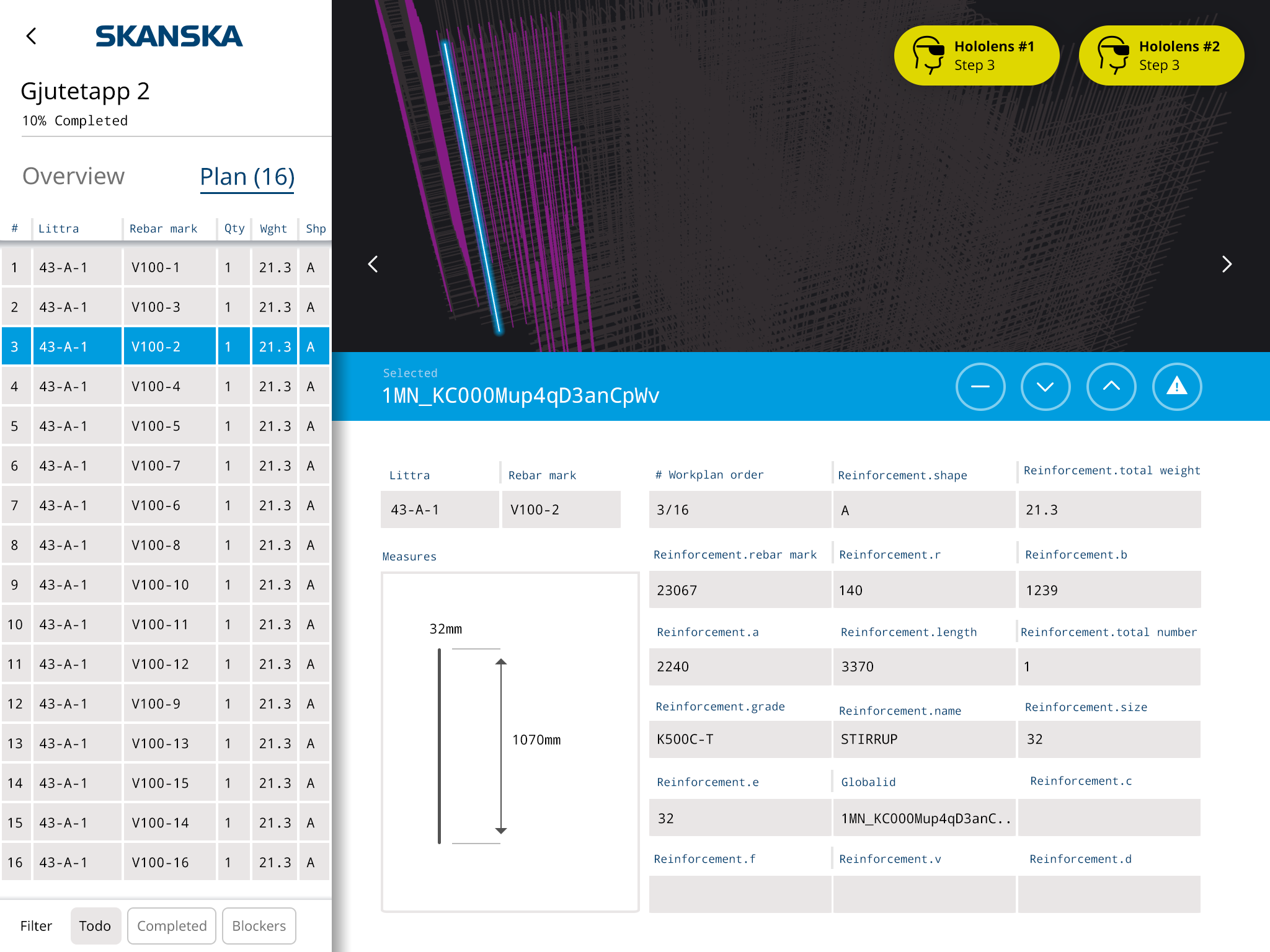

Screenshot from the mobile app, displaying properties from inside the BIM model allowing for easy grouping of components for detailed scheduling.

During the process, we learned the hard way that a building model is only of value if it contains accurate information – something that was surprisingly rare in real world projects. We turned to the designers and architects to learn more about the underlying issues. It turns out, that in order to have an accurate model of what you're building, the model needs to be created – and maintained – through the entire process. Twins are born at the same time.

"Twins are born at the same time"

Now, using requirements management software, creating a true digital twin is actually starting to become feasible, but updating it as it evolves during actual construction is still difficult. A digital twin isn't static, it needs to grow, and evolve, over time. To avoid vendor lock-in, it needs to be built using standardized schemas, such as IFC or REC, as the foundation to store information in the database, but every project also needs to be able to evolve their schema, adding just the pieces that they need.

In real world projects, working with 3D CAD can be slow and cumbersome. Updating information in the digital twin with huge "hand over packages" between stakeholders is a slow and error prone process. Instead, every peer should be able to access, and update, the information that is relevant to their task at hand. Using standard formats, such as BIM Collaboration Format (BCF), it becomes possible to create, and share, tasks and model snippets across any Open BIM compliant app or platform. While this may seem a distant goal, we're already seeing proof that the open source community can move faster - often much faster - than the incumbents that have to protect investments in legacy platforms. Here's another example, viewing an IFC model in a web browser, no additional software needed. It even works on a mobile phone! By allowing everyone on the project to share a single view that contains all information, common tasks such as getting hold of the updated version of some document, describing some particular aspect from the project, are no longer necessary. In fact, we won't be needing "project portals" to store our documents. Instead, the digital twin becomes the viewer to our many databases, a simple window to where all project information can be accessed, when we need it, where we need it.